Overview

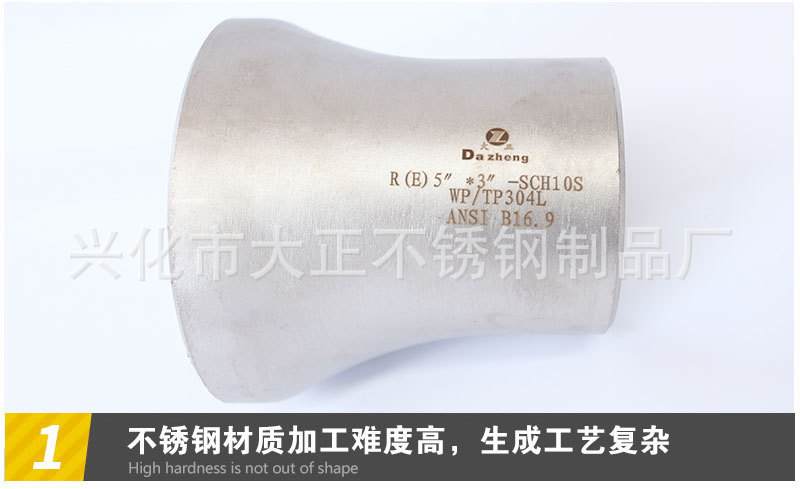

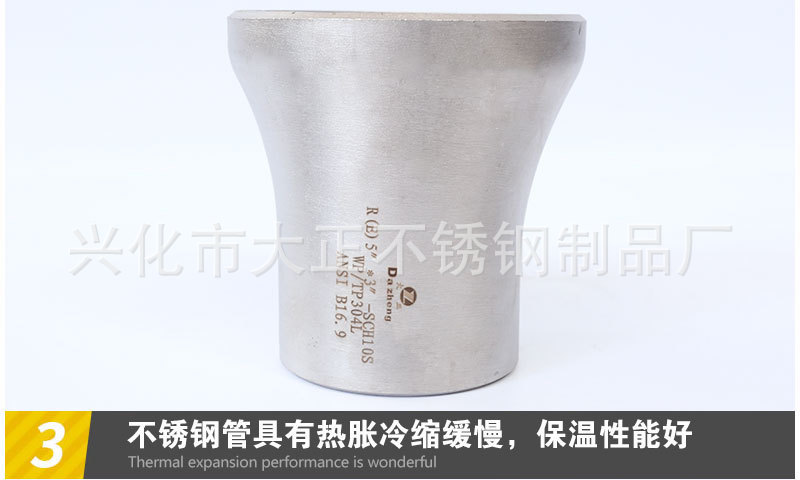

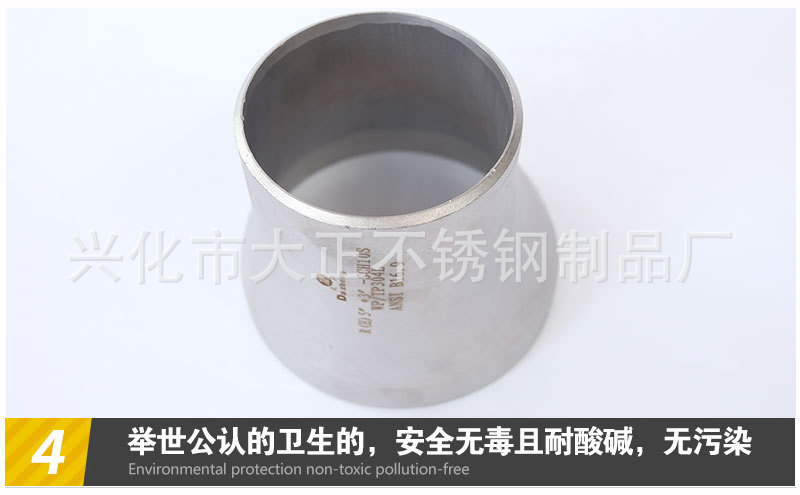

Eccentric reducer (Eccentric reducer) is a pipe for the pipe diameter, usually used in the forming process for the reduction of compression, expansion of the diameter or reduced diameter plus diameter suppression, for some specifications of the reducer Stamping can also be used

Structural features

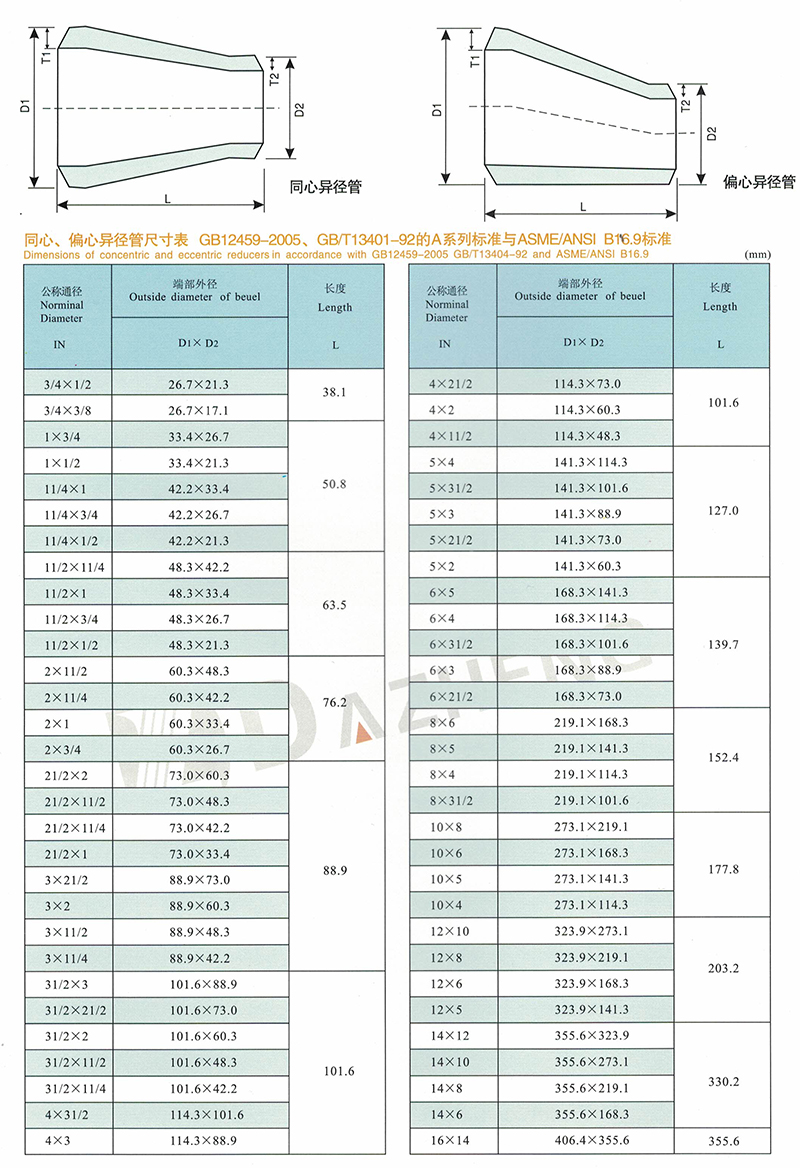

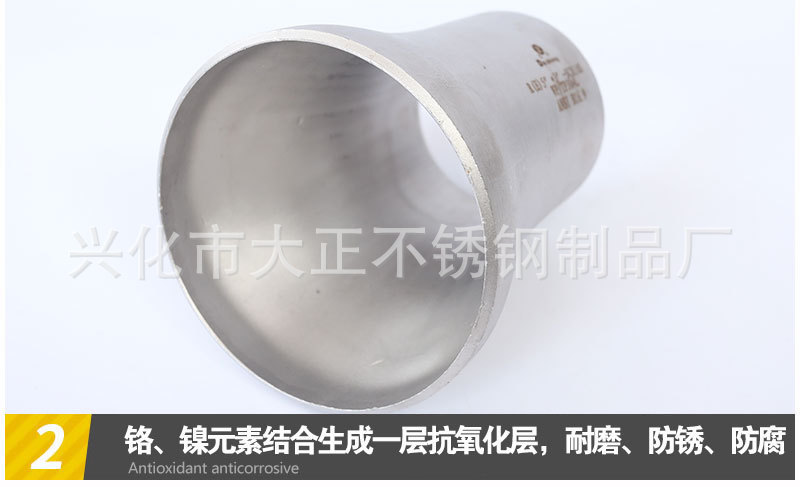

The roundness of the reducers should not be greater than 1% of the outer diameter of the corresponding end with a tolerance of ± 3 mm. ASTM A106 / A53 GRB, API 5L, APT5CT, ASTM A105, ASTM A234, ASTM A106, DIN German standard and customer requirements standards for the implementation of SY / T5037, GB / T9711, GB / T8163,

Reducer (size head) is a pipe for pipe diameter. The forming process is usually used to reduce the diameter of compression, diameter reduction or shrinkage plus diameter suppression, for some specifications of the reducer can also be used stamping.

Shrinkage / diameter forming

The reduced diameter forming process of the reducer is to place the tube billet having the same diameter as the large diameter of the reducer tube into the forming die, and the metal is moved and contracted along the mold cavity by pressing in the axial direction of the tube. According to the size of the reducer diameter, divided into a press forming or multiple press forming. The following figure shows the simplified shape of the concentric reducer.

The diameter of the tube is smaller than the diameter of the reducer tube diameter, with the inner die along the diameter of the tube diameter forming. The diameter of the main process to solve the variable diameter of the reducer is not easy to shrink through the shape of the situation, sometimes according to the material and product forming needs, the diameter and shrinkage method combined use.

In the process of reduction or expansion of deformation, according to different materials and variable circumstances, to determine the use of cold or hot pressure. Under normal circumstances, as far as possible the use of cold, but repeated changes caused by a serious hardening of the situation, thick wall thickness of the case or alloy steel materials should be used hot pressing.

B. Stamping

In addition to the use of steel pipe as raw material for the production of different-diameter tube, some of the specifications of the reducer can also be used steel plate stamping process for production. The die shape used for the drawing was designed with reference to the inner surface size of the reducer, and the steel sheet after the cutting was stamped and stretched.