Overview

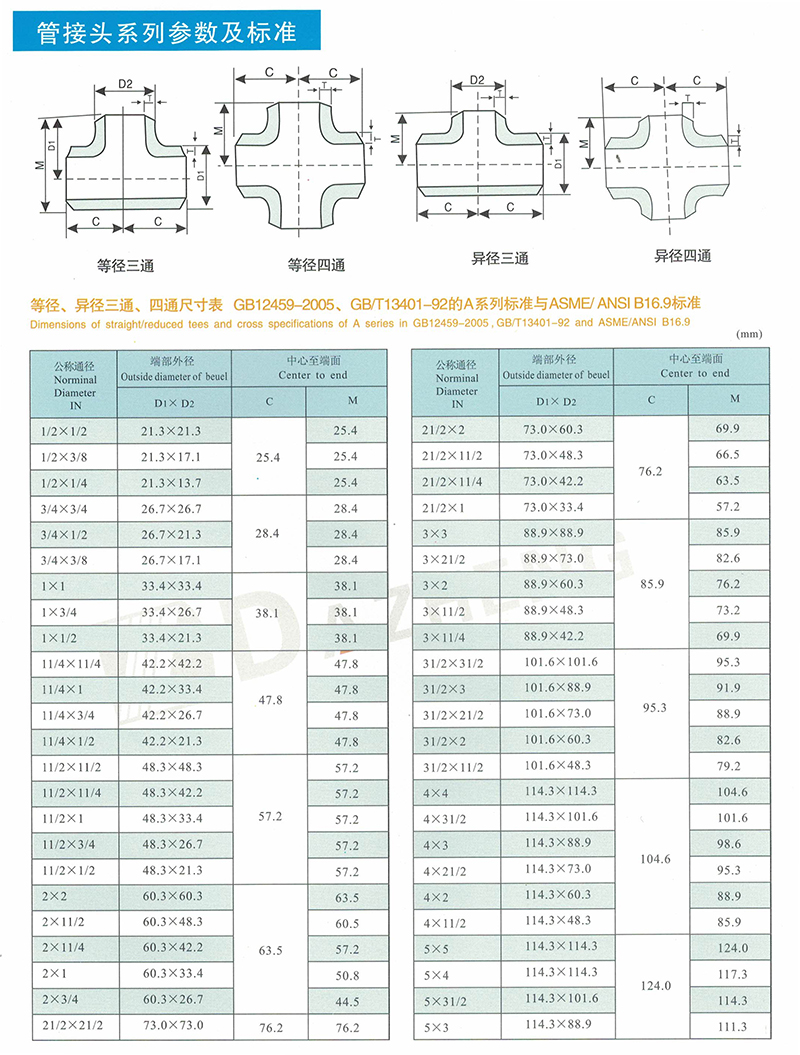

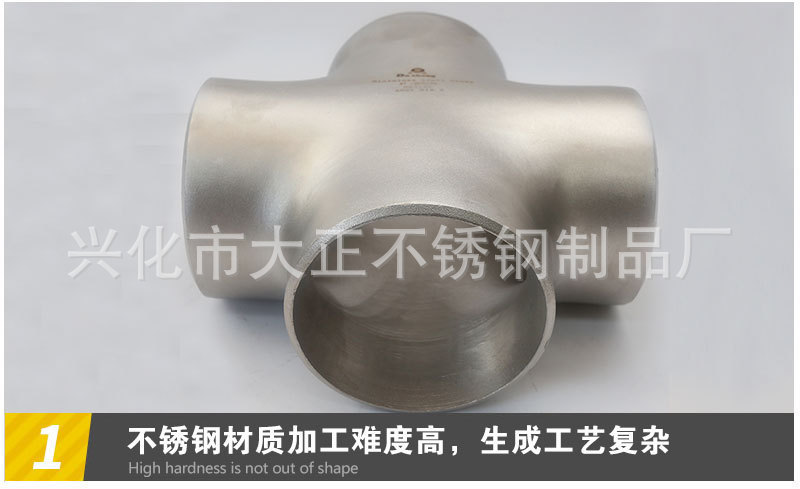

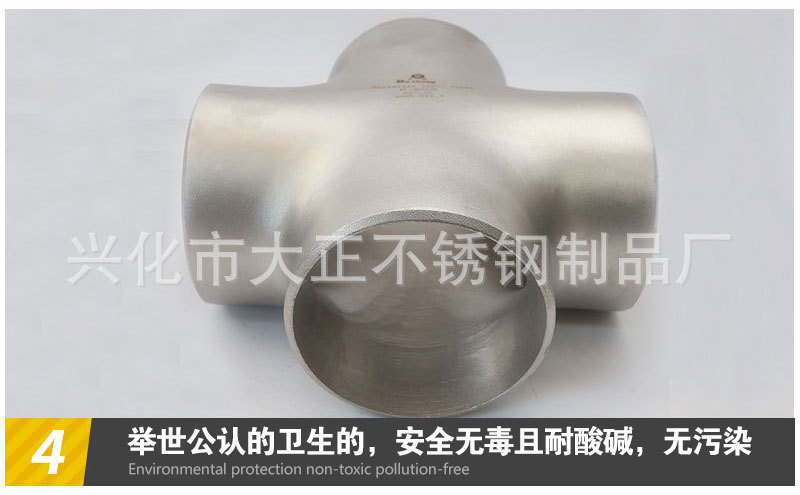

The diameter of the pipe is smaller than the size of the main pipe, and the size of the pipe is smaller than that of the main pipe. Stainless steel Stone is a pipe for pipe branch. For the use of seamless pipe manufacturing in terms of four, the current commonly used in the process of hydraulic bulging and hot forming two. A. The hydraulic bulging of the hydraulic bulge is a forming process that compensates the expansion of the branch pipe by the axial compensation of the metal material. The process is the use of special hydraulic press, will be equal to the diameter of the tube into the liquid tube, through the hydraulic machine two horizontal side of the cylinder to synchronize the movement of the tube extrusion tube, the tube is pressed after the volume becomes smaller, tube Of the liquid with the tube volume becomes smaller and the pressure increases, when the four-way pipe to expand the required pressure, the metal material in the side cylinder and tube under the dual role of liquid pressure along the mold cavity flow out of the branch pipe. Four-way hydraulic bulging process can be a forming, high production efficiency; Stone's head and shoulder wall thickness have increased. Due to seamless hydraulic bulging process required equipment tonnage larger, the current domestic mainly used for less than DN400 standard wall thickness of the four-way manufacturing. Its suitable forming materials are relatively low hardening hardening of low carbon steel, low alloy steel, stainless steel, including some non-ferrous metal materials such as copper, aluminum, titanium and so on. B. Hot-press forming Four-way hot-press forming is to be greater than the diameter of the tube diameter, flattened to about four-diameter diameter, in the extension of the branch pipe to open a hole; tube by heating, into the forming mold And the tube is filled with a die for drawing the branch pipe in the tube; under the action of the pressure, the tube is compressed in the radial direction, and the metal flows in the direction of the branch pipe during radial compression and forms a branch pipe under the drawing of the die. The whole process is formed by the radial compression of the tube and the stretching process of the branch portion. Unlike the hydraulic bulge, the metal of the hot-pressed faucet is compensated by the radial movement of the tube, so it is also called the radial compensation process. As a result of the use of heating after pressing the four-way, the material required to reduce the tonnage of equipment. Hot presses are more adaptable to materials, suitable for low carbon steel, alloy steel, stainless steel materials; especially large diameter and wall thickness of the four-way, usually using this forming process.