Overview

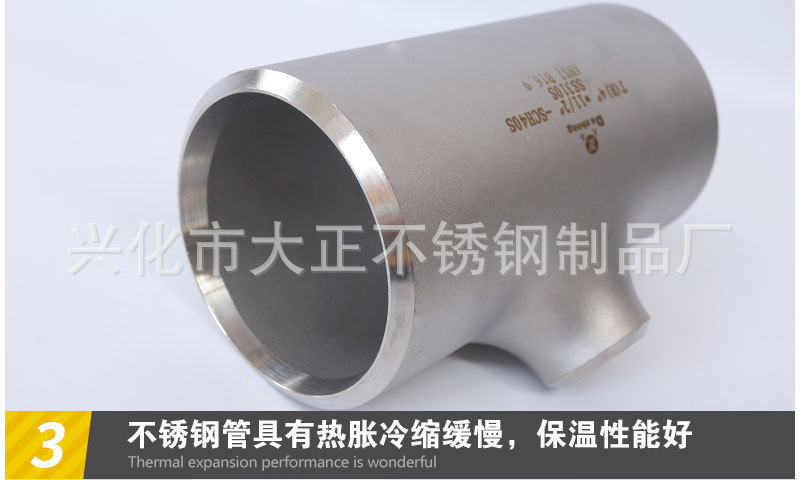

Reducing tee: The branch pipe is different from the other two diameters. Both ends of the same diameter is called equal diameter tee. Reducing Tee is widely used in petrochemical, oil and gas, liquefied petroleum gas, fertilizer, power plants, nuclear power, shipbuilding, paper, pharmaceutical, food hygiene, urban construction and other industries construction and maintenance.

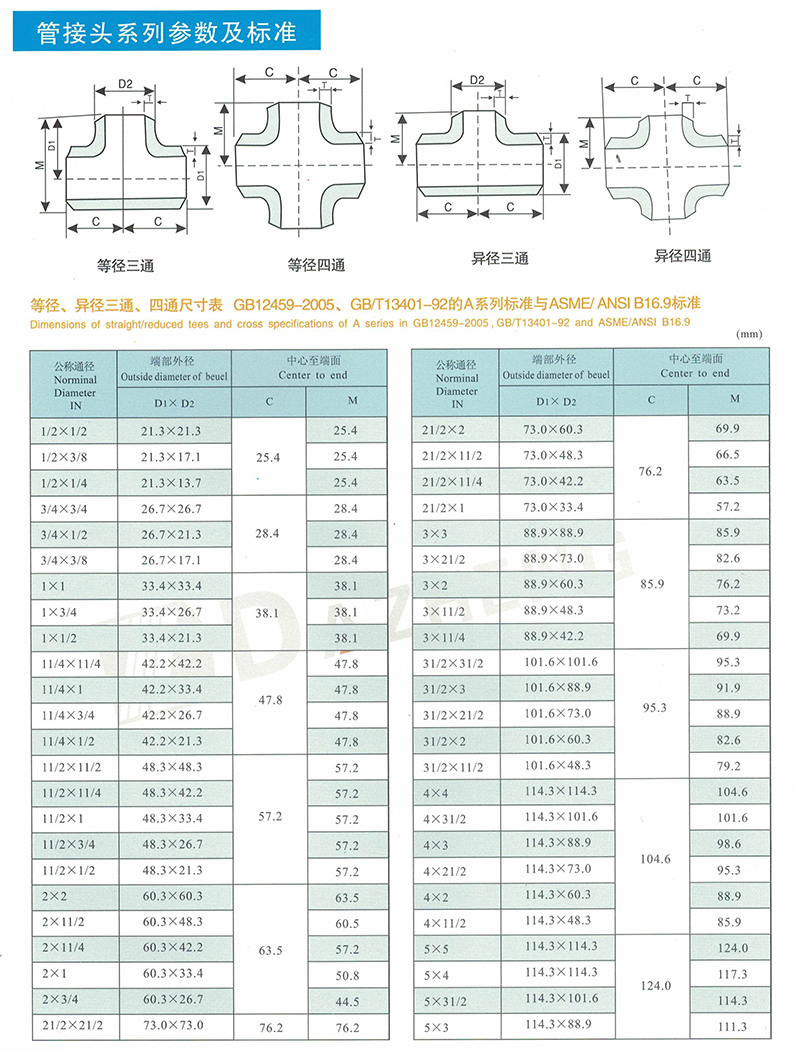

The representation is as follows:

For equal diameter tee, such as "T3" three-way means that the outer diameter is 3 inches of equal diameter tee. For Reducing Tee, such as "T4 × 4 × 3.5" means a diameter of three inches with a diameter of 3.5 inches. Material is generally 10 # 20 # A3 Q235A 20g 20G 16Mn ASTM A234 ASTM A105 ASTMA403, three links, diameter range of 2.5 "-60", from 26 "-60" for the welding three links. Wall thickness of 28-60mm. The wall thickness grades are Sch5s, Sch10s, Sch10, Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS; Sch80, Sch100, Sch120, Sch160, Reduced tee, generally professional terms, three links for the pipe, pipe fittings, used in the main channel to branch management. Reduced tee is a three-way, three links are generally equal diameter tee, reducer tee two. Because the three ends can be connected with the tube and named. Industrial pressure on this pipe is higher, the maximum pressure can reach 600 kg, the water pressure in life is low, generally 16 kg.

Tee can be used in a variety of industries, with different types can be divided into the following categories:

1. The production method can be divided into top system, pressing, forging, casting and so on.

2. The manufacturing standard can be divided into national standard, electric standard, water standard, American standard, German standard, Japanese standard, Russian standard and so on.

Material Description:

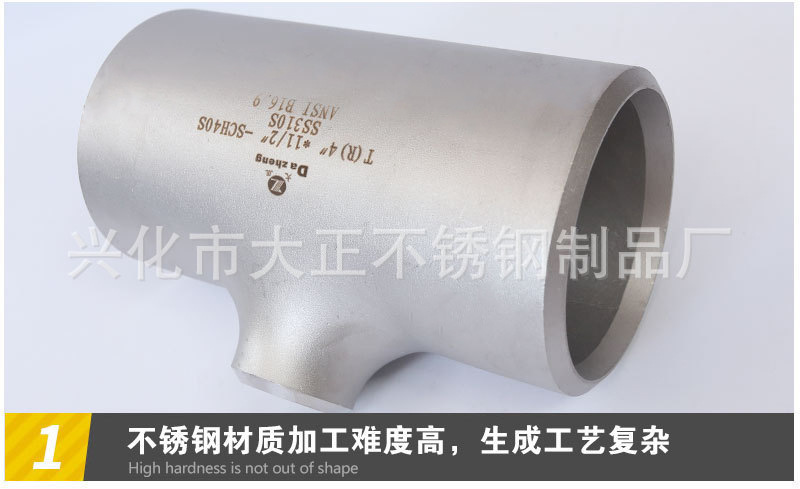

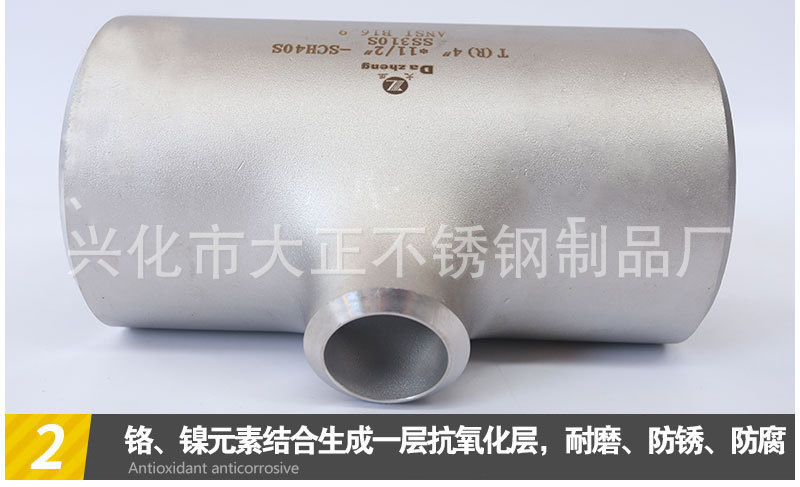

310S (0Cr25Ni20 / 0Cr25Ni20Si2), heat-resistant stainless steel, the density of 8.0 grams / cubic centimeter, 310S is austenitic chrome-nickel stainless steel, with good oxidation resistance, corrosion resistance,

Because it contains a higher percentage of chromium and nickel, has a high creep strength, can continue to operate at high temperatures, with good high temperature resistance.

Domestic brands: 0Cr25Ni20,

The United States grade: 310S,

Also known as 2520, duplex stainless steel, for high temperature furnace tube manufacturing.

310S chemical composition

Grade

Chemical composition (mass fraction) (%)

Ni

Cr

Si

Mn

C

S

P

310S

19.00-22.00

24.00-26.00

≤ 1.50

≤2.00

≤0.08

≤0.030

≤0.035

After the solution treatment of mechanical properties:

Grade

Yield Strength

tensile strength

Elongation

Hardness test

310S

≥205

≥520

≥40

HBS ≤ 187, HRB ≤ 90, HV ≤ 200

The main purpose:

310S stainless steel suitable for the production of a variety of furnace components, the maximum operating temperature of 1200 ℃, continuous use temperature 1150 ℃.

310S stainless steel tube is a hollow long steel, a large number of pipes used for conveying fluid, such as oil, natural gas, water, gas, steam, etc., in the engage in bending, torsion strength of the same, the lighter weight, so Also widely used in the manufacture of mechanical parts and engineering structures. Also used to produce all kinds of conventional weapons, barrels, shells.

310S stainless steel tube Product Description:

For the pressure of the steel pipe to be carried out by the hydraulic test to test its pressure capacity and quality, under the provisions of the pressure does not occur leakage, wetting or expansion of qualified, and some steel pipe according to the requirements of the standard or demand side of the curling test , Flaring test, flattening test and so on. 310S stainless steel pipe is made of steel ingot or solid tube through the perforated tube, and then by hot-rolled, cold or cold made.